What is LNG: A Guide to Liquefied Natural Gas

Liquefied natural gas (LNG) has emerged as a game-changer in the energy industry, revolutionizing how we transport, store, and utilize natural gas.

This extraordinary resource offers countless benefits and applications, from cleaner power generation to efficient transportation and industrial processes. Let’s explore the fascinating world of LNG, discover its diverse uses, and see how it's transforming how we think about energy.

What is Liquefied Natural Gas?

Known as LNG, liquefied natural gas transforms from a gas into a liquid after super-cooling to -260° F (-162° C). The liquefaction process removes most extraneous compounds, reducing natural gas to 1/600th of its original volume.

This makes it possible to safely and efficiently carry natural gas across long distances and even use it as a transportation fuel. But what is LNG fuel exactly? This term specifically highlights its usage as a versatile energy source capable of powering vehicles, ships, and industrial machinery, among other applications.

Benefits of Liquefied Gases

Liquefying natural gases offers advantages over maintaining their raw or compressed form.

- Liquefaction significantly reduces gas volume, allowing for more efficient storage and transportation. LNG occupies only 1/600th of its original volume, making it easier to handle and economically feasible to transport over long distances.

- The liquefaction process removes impurities and extraneous compounds from natural gas, producing a cleaner and more concentrated energy source. This purity enhances its combustion efficiency, reducing emissions of carbon dioxide, sulfur dioxide, nitrogen oxides, and particulate matter when compared to raw or compressed gas.

Types of Natural Gases Liquefied

LNG primarily consists of methane (CH4), the most abundant natural gas component. However, other natural gases, such as ethane (C2H6), propane (C3H8), butane (C4H10), and pentane (C5H12), can also be liquefied. These gases are typically separated during the liquefaction process to obtain pure LNG. Each gas has specific applications and uses, making this clean-burning fuel a versatile energy source.

LNG Storage Methods

Once liquefied, LNG is stored in specially designed cryogenic tanks and terminals, maintaining the low temperatures required to keep the gas in liquid form. These storage facilities employ advanced insulation techniques to minimize heat transfer and prevent vaporization. There are primarily two types of storage tanks used:

Onshore Storage Tanks: These are large, insulated tanks built on land. They're engineered with double-wall containment (an inner nickel-steel alloy tank and an outer concrete or steel tank) to store LNG securely. The space between the two walls is filled with insulation material, and the tank is equipped with safety relief valves to handle excessive pressure.

Floating Storage Units (FSUs): As the name suggests, these are floating vessels used to store LNG offshore. FSUs are typically employed in areas where land-based storage is not feasible or as a temporary solution to peak-shaving needs during high demand periods.

LNG Transportation Methods

Transportation is predominantly done via specially constructed LNG carriers equipped with insulation and containment systems that maintain the required temperatures and ensure safety. These vessels are designed to handle the unique properties of the fuel, including its extremely low temperature and potential for expansion. There are two main methods of LNG transport:

LNG Carriers: These are specially designed ships equipped with insulated tanks to transport LNG across oceans. Like the storage tanks, the carriers' tanks are designed to handle the cryogenic temperatures. The ships are fitted with advanced navigation and safety mechanisms to prevent spills and ensure safe passage.

Pipelines: While not suitable for overseas transport, pipelines are an effective way to move LNG over short to medium distances on land. The pipelines are made of materials that can withstand both the fuel's low temperature and the external environment. The liquefied gas can be transported through these pipelines from liquefaction plants to storage facilities or directly to regasification plants, where it's converted back into gas form for distribution to consumers.

LNG vs Raw and Compressed Gas

Raw natural gas, as extracted from underground reservoirs, contains impurities such as water vapor, carbon dioxide, sulfur compounds, and trace amounts of other hydrocarbons. Before liquefaction, these impurities are removed through various purification methods, resulting in a cleaner and more valuable product.

However, compressed natural gas (CNG) is achieved by compressing raw natural gas to pressures of up to 3,600 pounds per square inch (psi). While CNG offers advantages in terms of storage and transportation compared to raw gas, it still occupies a larger volume than LNG. The liquefaction process allows for a more significant reduction in volume, making LNG a more space-efficient option.

What is LNG Used For?

As the world seeks to reduce its carbon footprint, LNG serves as a bridge fuel, offering a cleaner alternative to coal and oil for various energy needs. Below are the key uses of LNG, demonstrating its versatility and growing importance in our daily lives and industries.

Energy

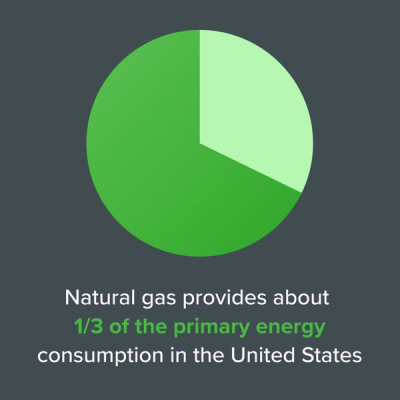

LNG plays a significant role in the energy sector, providing approximately one-third of the primary energy consumption in the United States. As the world's largest natural gas producer, the U.S. has been delivering natural gas to 40 countries on five continents.

It is a popular fuel choice for power generation because it’s a clean-burning fuel that produces fewer carbon emissions than other fossil fuels (like gasoline). Many power plants also use LNG as a backup fuel, storing it on-site in cryogenic tanks.

If demand peaks or supply drops, utility companies can revert LNG to its gaseous form and burn it to generate electricity.

Natural gas’s higher energy efficiency and reduced environmental impact contribute to its reputation as an “energy of the future.” Experts predict natural gas will account for 25 percent of the world’s energy portfolio by 2035.

Transportation

Using LNG as vehicle fuel requires maintaining its low temperature, limiting its use mainly to heavy-duty trucks, buses, and ships equipped for its cooling needs.

In addition, because trucks fueled by LNG are half as noisy as their diesel-fueled counterparts, they are often used in urban areas where noise pollution laws prohibit excessive truck traffic.

Converting LNG back into its gaseous state at room temperature is a simple process, allowing it to be used like natural gas for vehicles like cars, taxis, and public transit buses.

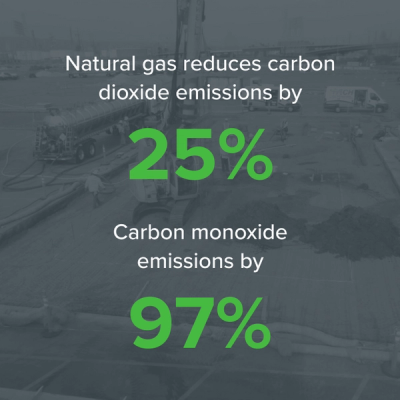

Compared to diesel fuel, natural gas reduces carbon dioxide emissions by 25 percent and carbon monoxide emissions by a whopping 97 percent, helping businesses and industries comply with strict environmental standards.

Residential and Commercial Heating

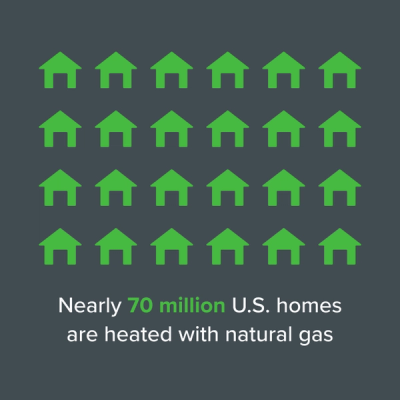

Natural gas is widely used for heating and cooking in residential and commercial buildings throughout the United States. Nearly 70 million U.S. homes are heated with natural gas, making it the most popular fuel for home heating.

However, thanks to significant strides in natural gas fuel’s energy efficiency, overall consumption has remained the same over the past several decades, while the number of homes heated with natural gas has risen.

Additionally, over 5 million commercial customers, including hospitals, schools, restaurants, and offices, utilize natural gas for space and water heating.

Because the commercial sector has grown over the years, the average utility bill that commercial customers pay for natural gas has declined significantly since 1975, reaching a new low of $405 in 2015.

Raw Materials

The industrial sector accounts for about one-third of natural gas consumption in the United States. Many manufacturers rely on natural gas to create critical products such as paper, glass, plastics, steel, iron, and bricks.

LNG's unique properties make it an excellent choice for various metal heating processes, including melting, reheating, and thermal treatments. Additionally, natural gas is crucial in producing fertilizers, plastics, medicine, synthetic fiber clothing, paints, cosmetics, and other petroleum-based products. The chemical and textile industries also utilize natural gas for steam production.

Choose FASTECH For Your Alternative Energy Needs

With the LNG industry on the cusp of substantial growth, driven by its clean, versatile nature, FASTECH stands ready to guide organizations through this evolving energy landscape.

The surge in LNG infrastructure—encompassing production, storage, and regasification—aims to satisfy the increasing global demand and open access to LNG for emerging markets. Innovations like floating LNG (FLNG) facilities and small-scale projects promise more adaptable and cost-effective LNG solutions, especially valuable for remote areas.

Over 100 projects across the U.S. demonstrate LNG's broad applicability, making it a compelling alternative fuel choice. For over two decades, global industrial energy leaders have trusted FASTECH for to provide alternative energy solutions and clean fuel consulting services. Our team specializes in end-to-end solutions, from planning and construction to ongoing maintenance and compliance for hydrogen, CNG, LNG, and propane.

To learn more about embracing alternative energy and reaping its benefits, contact FASTECH today.